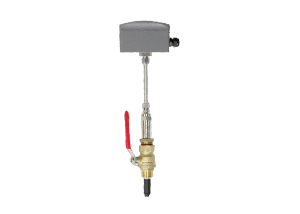

The insertion flowmeter suits pipe diameters ranging from 200 to 3000 mm. For optimal placement, consider installing them at the outlet of wells with consistent flow rates. Particularly for pipes over 400 mm in diameter, where using a flanged magnetic flowmeter proves costly, this option shines if the installation site remains undisturbed.

Critical prerequisites for installing this flowmeter include:

A. Uninterrupted, straight pipe sections before and after sensor installation, devoid of elbows, valves, etc. The pre-installation distance should be at least 10 times the pipe diameter, while the post-installation distance should be 5 times the diameter. This guarantees a tranquil, undisturbed water flow at the sensor point for the most accurate measurements.

B. Water flow velocity ranging from 50 cm to 1.5 meters per second ensures optimal measurement accuracy. Speeds below 50 cm compromise accuracy, focusing measurements solely around the sensor and neglecting the entire pipe cross-section. Flow rates surpassing 1.5 meters per second might not meet the necessary conditions for proper liquid flow.

Important features

Observing the instantaneous flow through the pipe

View the total flow

Dubai information transfer

The water flow control

Affordable price

Benefits of insertion electromagnetic flowmeter for intelligent management of water resources

Very reasonable price = savings:

The device boasts an all-domestic manufacturing process, setting it apart with a price that might seem less competitive against foreign counterparts. However, this local production ensures substantial savings for consumers, thanks to readily available parts and comprehensive internal technical support and calibration services. Choosing this option means saving considerably compared to purchasing from overseas sources.Since all parts of this device are manufactured inside the country, it has an uncompetitive price compared to foreign samples. At the same time, due to the support of parts and internal technical and calibration services, the consumer saves a lot compared to buying from abroad.

Easy installation:

Installing this device is a breeze, requiring minimal water flow interruption. No additional pipes or bypass valves are necessary—all it takes is drilling a hole with the bushing’s diameter at the desired spot or welding a 50 mm diameter bushing onto the pipe. Alternatively, for asbestos, concrete, or non-metallic pipes, belts with pre-installed bushings can be utilized.

Easy maintenance:

The inclusion of the one-way valve on the pipe simplifies potential sensor transfer and replacement without disrupting liquid flow—an effortless process. With long-term internal part support, future device maintenance poses no challenges. Plus, under favorable hydraulic fluid conditions, the pipeline and device installation won’t demand specialized upkeep, resulting in remarkably low maintenance costs.

Easy to use:

This device is designed and built according to the environmental requirements of the country for operators with a low and medium level of knowledge in such a way that its sensitive parts are far from the operator’s reach, and on the monitoring and control board, all the settings of the flow measurement operation can be followed by pressing the minimum number of buttons.

Industrial design and construction with excellent strength:

The device’s design and construction prioritize robustness, ensuring optimal performance even in challenging environmental hydraulic conditions. The sensor enjoys comprehensive protection against dust, humidity, rust, electrical interference, vibration, rain, and temperatures spanning from -20 to +60 degrees Celsius. This sturdy build guarantees reliable operation in varied and demanding settings.

Internal parts and service support:

Due to the design and manufacture of all parts of this device in Iran, it has a one-year warranty and ten-year technical support.

Performance Theory:

The operational theory aligns with that of the MagAb magnetic flowmeter, although with a key distinction. The MagAb flowmeter, measures and correlates the speed of millions of water molecules within the flowmeter cylinder; contrastingly, this device solely measures the velocity of water molecules passing through the sensor cavity at the one-eighth point of the pipe diameter.