Principles of ultrasonic level meter operation

Ultrasonic level meters are appropriate choices for level metering in situations where contact with the liquid surface is not possible. In this type of level meter, the ultrasonic sensor calculates the desired height by sending an ultrasound wave and obtaining the flight time of the wave.

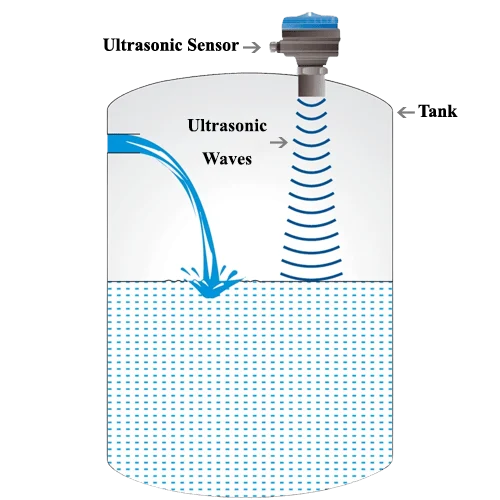

When ultrasonic waves are transmitted to the surface of the fluid inside of the tank, they face different densities and are reflected from the surface and return to the sensor. duration of transmitting and receiving this signal is directly proportional to the distance of the sensor from the fluid surface.

(The figure below shows the operation of the ultrasonic level meter schematically):

Since the speed of sound is known and constant, the distance can be calculated by measuring the round trip time.

In an ultrasonic level meter, the distance between the fluid surface and the top of the tank (sensor installation location) is first measured, and then the level measurement is calculated by subtracting the difference between this distance and the tank height.

Transducer sensor which include piezoelectric crystals, send and receive ultrasonic signals. When electrical energy is applied to the piezoelectric crystals, they start to move and an ultrasound signal is produced. When the sound wave returns, the displacement of the returning ultrasound wave produces an electrical signal that is manifested as a return pulse. Round-trip time is measured as the time between sending and returning a signal.

This sensor is suitable for all types of water tanks, paint tanks, sand tanks, milk tanks, any type of tank that includes liquids, flammable liquids, viscous materials, etc. Also, in explosive environments, chemical tanks with higher corrosiveness, ultrasonic level meters can also be used.

It is worth mentioning that this sensor cannot be installed in dense dust such as cement tanks and tanks with strong boiling water vapors.

In general, the following problems caus loss of surface clarity:

- A layer of foam on the surface of the liquid

- Soft and small crumbs on bulky raw materials

- Dust cloud produced by the transfer of ore and ore

After sending the pulse and returning the echo and receiving it, another pulse will be sent by the sensor. Because the ultrasonic signal moves at the speed of sound, the time between sending and receiving is equivalent to the surface distance. The distance that can be measured in this way should be in the range of 0.5 to 10 meters.

The relationship between the distance of the sensor and the liquid surface is as follows:

\(d= \frac{1}{2}vt \)

d = surface distance from sensor

v = speed of sound = 331.5 m/s

t = round trip time of the signal