Ultrasonic Flow Meter

Ultrasonic flowmeters are widely recognized as essential tools for flow measurement in various industries. This technology finds extensive applications in sectors like oil and gas, petrochemicals, water and wastewater, as well as steel and cement production.

In this article we are going to discuss these topics:

The operational principles of ultrasonic flowmeters

Ultrasonic flowmeters employ ultrasonic waves to measure the fluid flow rate. The sensors come in either transit time or Doppler types. These sensors operate without the need for direct contact with the fluid, making them ideal for numerous applications such as measuring flow rates within pipelines.

Transit-Time Flowmeters

This device operates on the Transit-Time principle, tailored for clean fluids free from suspended particles or turbidity.

In this method, two ultrasonic sensors are positioned in different sections of the pipeline. One sensor acts as a transmitter, directing waves towards another sensor in the flow direction, while the latter serves as a receiver, capturing the transmitted waves.

The process is then reversed. The receiver sensor will play role as transmitter one, sending waves against the fluid flow for another sensor to catch.

Using this alternative signal sending method, the fluid velocity is determined by calculating the time difference between the two sensors. Coupled with data on velocity, pipe cross-sectional area, and the speed of sound, both instantaneous and cumulative flow rates are precisely computed.

For more information, visit the page on Ultrasonic Transit Time Flowmeters.

Doppler Flowmeters

Doppler flowmeters take the stage when it comes to measuring the flow rate of fluid streams laden with suspended particles, bubbles. or turbidity.

In these flowmeters, an ultrasonic wave with a specific frequency is dispatched into the pipe via a sensor. A portion of this ultrasonic energy interacts with particles within the fluid, bouncing back to the sensor with a frequency distinct from the initial one. Disparity between the frequency of the initial and the returning signal is directly proportional to the fluid’s velocity.

For more information, visit the page on Ultrasonic Doppler flowmeters.

Ultrasonic transit-time flow meters applications

Ultrasonic flow meters have diverse applications in flow measurement inside pipes, open channels, and partially-filled pipes.

These applications are widespread across various industries. Examples of such cases include:

- Oil and Gas

- Water and Wastewater

- Food and Pharmaceutical

- Agricultural

- Automobile

- Cement

- Petrochemical

- Mining

- Tile and Ceramic

- Power Generation and Distribution Plants

The advantages of using ultrasonic flowmeters

Some of the key advantages of this type of flowmeters include:

- Non-contact Operation and No Impact on Fluid Flow

- Easy Installation and Operation

- No Need for Mechanical Changes to Pipe Path in Cases Where Extremely High Precision Is Not Required

Ultrasonic Flow Meter Installation Guide

With a notice of pipe diameter size and also setting suitable conditions for recording the sending and receiving time

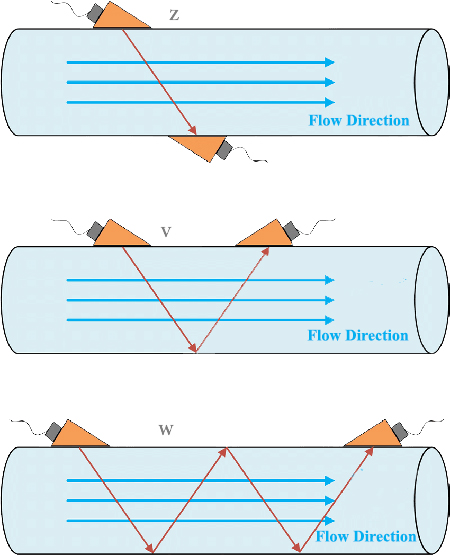

Considering the size and diameter of the pipe, as well as ensuring optimal conditions for recording signal transmission and reception times, three main types of ultrasonic sensor installations are considered as follows:

- Z-Type Installation

- V-Type Installation

- W-Type Installation

Z-Type Installation

In situations where the pipe diameter is substantial, this installation type is utilized to prevent time loss. It ensures that the sensor can receive the signal before its attenuation, allowing the sensor to register its departure time promptly, enabling swift acquisition of fluid velocity and flow rate.

V-Type Installation

For small to medium-sized pipes, this standard installation is employed. During installation, precise positioning of the two sensors on the pipe is essential to receive high-quality ultrasonic signals. In this configuration, the emitted signal initially encounters the lower pipe wall and then reflects towards the second sensor. One advantage of this method is that, due to the small to medium pipe diameter, the signal travel time slightly increases to be measurable by the system. Additionally, the transmitted signal reaches the receiving sensor with suitable quality.

W-Type Installation

When dealing with pipes of very small diameter, this installation type is crucial. It requires multiple reflections inside the pipe before the transmitted signal reaches the receiving sensor. This slightly increases the signal travel time ensures that the signal is measurable with quality for the system.